Ball mill trunnion YouTube

#0183;#32;CHAENG is specialized in manufacturing large steel casting parts for ball mill: ball mill trunnion, ball mill main bearing, ball mill bearing pedestal, ball mill girth gears and so on

WhatsApp)

WhatsApp)

#0183;#32;CHAENG is specialized in manufacturing large steel casting parts for ball mill: ball mill trunnion, ball mill main bearing, ball mill bearing pedestal, ball mill girth gears and so on

Trunnion bearings. In mechanical engineering, it is one part of a rotating joint where a shaft (the trunnion) is inserted into (and turns inside) a full or partial cylinder. Often used in opposing pairs, this joint allows tight tolerances and strength from a large surface contact area between the trunnion

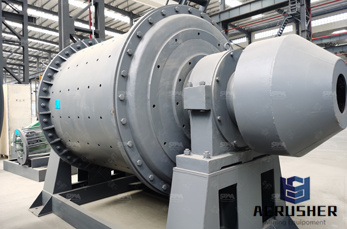

Ball mill trunnion (ball mill hallow shaft) is an important part to load the mill rotary body The neck that connected to bearing liner and the circular that connected to mill shell shouldnt cast with defects, such as, pore and sand hole The neck that connected to bearing liner should have polishing machining and make sure its precision and smoothness So it has strict requirement for casting

#0183;#32;Advice for contacting me: https:///in/dominikboemer

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

You can also choose from broaching, ball mill ball mill trunnion There are 98 suppliers who sells ball mill trunnion on, mainly located in Asia. The top countries of suppliers are China, India, from which the percentage of ball mill trunnion supply is 98%, 1% respectively.

The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load. Usually it is constructed from Babbitts metal. If you happen to remember the introduction to this course Issac Babbitt was the man who devised the method of bonding selflubricating metals onto a strong backing to form a bearing

We are the world leader in designing and supplying highly engineered grinding mill liners for SAG, AG, ball and rod milling. OVERVIEW Our innovative liner designs and proven alloys maximize mill performance and availability while minimizing costly down time.

Buy Trunnion Liner For Ball Mill from King Industries. Request a quote online today. Used Mining amp; Processing Equipment Grinding Mills, Crushers amp; Process Plants

We provide both original body liners and spiral/impeller liners designed as a system for each of the mill sizes of Metsos extensive range of stirred media mills. Our product range includes all the consumables in your mill body liners, screw liners, impeller arms, retaining screens and attachment hardware.

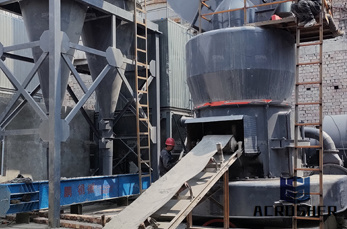

trunnion Industry in ball mill pdf file. Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment.

In a rotary grinding mill or the like the inlet and discharge trunnions of the mill are respectively provided with a liner assembly comprising a radially outer or primary liner and a radially inner or secondary liner. The primary liner normally remains permanently installed and is provided with a pair of axially spaced tract slots of Tshaped cross section.

When the ball mill cylinder rotates, the grinding body acts on the cylinder liner due to the action of inertia and centrifugal force and friction. It is carried away by the cylinder. When it is brought to a certain height, it is thrown off due to its own gravity. The falling abrasive body crushes the material in the cylinder like a

The Mill Trunnion Liner fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing as it is fed to or discharged from the mill. The difference in the trunnions at each end of the mill isnt in the trunnions themselves. The trunnion liner on the feed end of the mill may have a WORM to assist the ore into the mill. This worm acts like

trunnionoverflow Spanish When operating an overflow mill with a higher charge escaping balls are returned to the mill by a reverse spiral in the trunnion liner or are restrained by a ball Purchase and removal of mill conversion of rod mill to ball mill including new discharge trunnion liner and double man hole doors

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

The magnetic metal liner has also found applications in large ball mills, such as the m (D) x m (L) mills installed at Diaojuntai concentrator in Qidashan Iron Ore Mines. Another advantage of the magnetic metal liner is that as the liners are thinner and lighter than conventional manganese steel, the effective mill volume is larger, and the mill weight is reduced.

trunnionoverflow Spanish When operating an overflow mill with a higher charge escaping balls are returned to the mill by a reverse spiral in the trunnion liner or are restrained by a ball Purchase and removal of mill conversion of rod mill to ball mill including new discharge trunnion liner and double man hole doors

Semiautogenous grinding (SAG) mill liner design The AusIMM. generate both thrown and cascading ballmilling actions with shell linings.. pulp out of the mill through the trunnion

WhatsApp)

WhatsApp)