Global Chromium Mining Market Overview with Qualitative

Chromium | Minerals Education Coalition

WhatsApp)

WhatsApp)

Chromium | Minerals Education Coalition

chromium ore mining techniques. Chromium Mining Processing Equipment Flow Chart . Chromium (Cr) is a hard, bluish metallic element. The only ore of chromium is the mineral chromite and 99 percent of the worlds chromite is found in southern Africa and Zimbabwe. Geologists estimate that there are about 11 billion tons of mineable chromite ore

generalized Cr material ow diagram, from chromite ore mining to end use, is shown in Fig. Fig. represents a material ow diagram for Cr, from import to export, from manufacturing

In the acidic process, the ore is either leached with sulfuric acid or reduced to form ferrochromium, which is ground and dissolved in sulfuric acid. Iron is removed by crystallization as ferrous ammonium sulfate. The chromium in the solution is used to produce electrolytic chromium.

CHROMEORE IN INDIA : ITS STRATEGIC IMPORTANCE CHROMEORE IN INDIA 273. MetallurgicalThe most important application of chromite is in the manufac ture of ferroalloys used in making chromium steels.

Chromite deposits are mined by both underground and surface techniques. Much of the ore is rich enough to be used directly: for production of ferrochromium, a rich, lumpy ore containing more than 46 percent Cr 2 O 3 and having a chromiumiron ratio greater than 2:1 is preferred, but ores with a lower ratio and as little as 40 percent Cr 2 O 3 are also used. (Ores high in alumina are preferred for

The task is solved in that in the method of enrichment of chromium ores, including crushing, screening divided into classes, the subsequent xray radiometric separation of ore from the separation of the product concentrate and tails and subsequent processing of the latter conventional technology, according to the invention xray radiometric separation is realized with two threads, the respective sizes 150

Chromium was given the name such after the Greek word that spells quot;Chromaquot; that means color, for the reason of the many colorful compounds made from it. Chromium is mined as chromite (FeCr2O4) ore. About 2/5ths of the chromite ores and concentrates in the world are fashioned in South Africa, while Kazakhstan, India, Russia, and Turkey are also

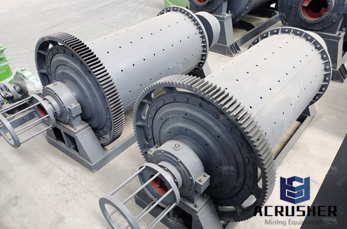

2. The smaller crushed chrome ore is fed to ball mill for grinding. Inside the ball mill, the crushed chrome ore will grind the ore to about mm with 3inch steel balls. 3. Screened products are transported to the jig for rough separation and to three concentrating tables for fine separation.

Rock containing chromite ore Mining Method Extraction of the Chromite Ore Both surface and underground mining methods will be used to mine the chromite. Mining produces both ore and waste rock. Waste rock consists of all other nonchromite bearing rock excavated during mining. Surface Mining Chromite ore is mined by surface methods.

Chrome ore deposits are mined by both underground and surface techniques. most chrome ore must be processed by the chrome ore processing plants. the mainly chrome ore beneficiation method is gravity separation. so the mainly used chrome ore concentrating equipments are ore washbox (sometimes it is called jigger), concentrating table, spiral

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group is a steelygrey, lustrous, hard and brittle transition metal. Chromium is the main additive in stainless steel, to which it adds anticorrosive is also highly valued as a metal that is able to be highly polished while resisting tarnishing.

Chromite ore is prepared for processing using several methods, depending on is determined by the chromite ore''s chromium to iron The production of. Read more. A large percentage of the world''s economically mineable chrome ore Two underground mining methods are employed at the Samancor Chrome mines,...

Chromium Ore Mineral Processing. Chrome Ore, Chrome Recovery, Chrome Mineral, Chrome . Chrome ore deposits are mined by both underground and surface techniques. most chrome ore must be processed by the chrome ore processing plants. the mainly chrome ore beneficiation method is gravity separation. so the mainly used chrome ore concentrating equipments are ore washbox (sometimes it

To find the mineral, miners searched for a small piece of ore called float and followed it to the deposit, which is often in the shape of a lensshaped pod. They worked small isolated deposits with hand tools. Larger deposits justified the cost of using dynamite, air compressors, jackhammers, and loading shovels/excavators.

Like mining, beneficiation (processing, crushing, separating, smelting, refining, etc.) for chromite depends on the characteristics of the ore deposit and on the mining methods used. For example, an operation extracting only highgrade ore may require only hand sorting and screening.

The mining of laterites is basically an earthmoving operation, with large shovels, draglines, or frontend loaders extracting the nickelrich strata and discarding large boulders and waste material. The ore is loaded into trucks at the face, as would be the case in an open pit, and hauled to the smelter.

Because surface mining typically is less expensive than underground mining, it is preferred, but not always possible. Like mining, beneficiation (processing, crushing, separating, smelting, refining, etc.) for chromite depends on the characteristics of the ore deposit and on the mining methods used. Extraction of Chromium from Chromite Ore Ore SamplesChromite Ore ProcessingChromium Ore

How To Extract Chromium From Chromite Ore. Extraction of chromium from chromite ore 911 metallurgist the average grade of the metallurgical chromite ore was pct cr2o3 with 52 pct of the method of extracting chromium values from chromite ore by digesting the ore with a molten bisulfate separating the isolubles and electrolying the digest fluid to yield an immiscible.

What is Chromite? Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr 2 O 4).It is dark gray to black in color with a metallic to submetallic luster and a high specific gravity. It occurs in basic and ultrabasic igneous rocks and in the metamorphic and sedimentary rocks that are produced when chromitebearing rocks are altered by heat or weathering.

Case Study: Chromite mining and health concerns 5 Chromium mining and processing In nature, chromium is found as chromite ore, composed of elemental iron, oxygen and chromium (FeOCr 2 O 3). 1,2 heavily in about a 700 m vicinity around the Countries with commercially significant chromite mines include Russia, South Africa, Zimbabwe, Turkey, the

WhatsApp)

WhatsApp)