Industrial IoT Applications For Conveyor Belt DZone IoT

In this post, we take a look at the Industrial IoT applications for conveyor belt systems, specifically the mining, manufacturing, and warehouse sectors.

WhatsApp)

WhatsApp)

In this post, we take a look at the Industrial IoT applications for conveyor belt systems, specifically the mining, manufacturing, and warehouse sectors.

Conveyors in mining international conveyor belt systems has launched what it describes as a revolutionary conveyor belt monitoring system, the phoenoguard is an allforone 24/7 device, which detects any deficiency of a moving conveyor belt .

Belt conveyor systems belong to the category of continuous conveyors and are used all over the world for bulk material handling over long distances, for example, in openpit mines, such as the lignite areas in Germany or copper mines in Chile.

#0183;#32;Phoenix Conveyor Belt Systems has launched what it describes as a revolutionary conveyor belt monitoring system, the Phoenoguard PX. It is an allforone 24/7 device, which detects any deficiency of a moving conveyor belt inside (gt; steel cords, textiles, splices) and outside (

54,445 mining conveyor belt products are offered for sale by suppliers on, of which conveyors accounts for 35%, rubber belts accounts for 4%, and transmission belts accounts for 2%. A wide variety of mining conveyor belt options are available to you, There are 54,173 suppliers who sells mining conveyor belt on, mainly located in Asia.

Conveyor Systems With extensive experience in the mining industry, the engineers at CDG specialize in the design, analysis and simulation of bulk material handling conveyor systems. Whether you are trying to assess your existing mining conveyor system to address product loss or efficiency issues such as speed and capacity, or you are

Belt conveyor systems continuously transport all forms of material, including excavated and crushed rock, in an efficient manner due to their effective availability. They cover a wide range of applications, from mining or extraction to inplant or overland where they convey material over long distances, passing through curves and rough relief areas.

To keep pace with the rate of advancement in mining, belts often need to be shortened or lengthened with relative ease. The Voith TurboBelt Storage Loop System enables changing the length of belt systems in a safe and productive manner. The conveyor belt is looped around 26 return pulleys with 13 pulleys mounted on a moving tensioning car.

UNIFLEX #174; Highperformance conveyance in underground coal mining; Special conveyor belts. PHOENOFLEX #174; Has a tensile member made of steel cords that are additionally interconnected with textile or steel threads, for transporting hot bitumen. PHOENAMID #174; With tensile members made of aramid cords, for special applications that demand a combination of low elongation, low weight, and

Phoenix Conveyor Belt Systems has launched what it describes as a revolutionary conveyor belt monitoring system, the Phoenoguard PX. It is an allforone 24/7 device, which detects any deficiency of a moving conveyor belt inside (gt; steel cords, textiles, splices) and outside (gt; rubber covers).

Mining Conveyor Belt Monitoring Trolex Ltd. Phoenix Conveyor Belt Systems is the global technology leader for the design and production of tailormade conveyor belt systems. Phoenix steel cord and textile conveyor belts operate in a reliable, economical, and environmentally friendly manner, in surface and underground mining. Click Here

Belt Management / Conveyor Control BRS2. The Belt Rip Detection System BRS2 has been developed to help increase the productivity of conveyor belts by detecting belt rips as soon and as reliably as possible. It increases the productivity of conveyors through the immediate detection of belt rips at noticeable, monitored points.

As a development partner and original equipment supplier in the mining sector, we supply highend technologies for a variety of applications. While our conveyor belts enable the efficient transport of materials, our drive belts and undercarriages ensure optimum performance in construction vehicles. As a system supplier, we fully equip systems and

#0183;#32;PHOENIX is the leading manufacturer of high quality conveyor belting for the worldwide mining industry. This covers all kinds of belting for all applications, for use underground or above ground. PHOENIX provides customised conveyor belts for highly complex applications throughout the world:

Phoenix Conveyor Belt Systems produces heavy weight conveyor belt for mining locations and a variety of industries around the world. Our expertise and experience has produced significant advancements in conveyor belt design, including world records for the strongest belt (both textile and steel cord), the steepest overland and worlds heaviest belt.

Look for industry pioneers capable of designing innovative systems that specifically address your sites needs. How Innovative Mining Belt Conveyor Manufacturers Can Improve Your Site . When you choose to work with mining belt conveyor manufacturers who are world leaders in

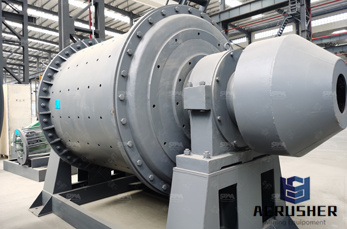

Mining belt conveyor system machine. Brand: Zhenying Packaging: Plywood case Supply Ability: 100 set/month Min. Order: 1 Set/Sets Mining belt conveyor system machine Description Mining belt conveyor system machine to connect into a closed loop tensioning them by tensioning device According to the friction between the belt and driving roller by the drive of motor conveyor belt continuous

Closedtroughed conveyor belt systems Sidewall belts Highelevation shortdistance conveying / 16 Steepangle conveyor belts Vertical conveying / Maximum elevation 18 singleflight conveyor belts Underground mining / Certified 19 conveyor belts for underground application Separating fluid and solid components / 20 Vacuum

Custom Mining Conveyor Packages. Whether youre starting with a used conveyor system, rebuilding an existing one, or starting from scratch with a new, custombuilt system, we have the experience, resources and capability to assemble the perfect conveyor package for your application.

WhatsApp)

WhatsApp)