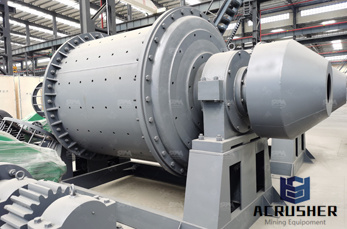

Ball mill, Grinding machine, Wet ball mill, Dry ball mill

#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

WhatsApp)

WhatsApp)

#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

plant of DADRI 2 x 490 MW FGDF systems. for Wet Ball Mill system as per AnnexureI amp; submit the Annexure to qualification requirement (Annexure3K) TECHNICAL SPECIFICATION OF LIMESTONE GRINDING SYSTEM NTPC limestone slurry feed tank (A or B) and underflow return to inlet of ball mill. And at recirculation

Ball mills are the classic grinding plants: Around the world they are the most common installations. Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. By using ball mills in closed circuit with a separator, their efficiency can be increased even further.

Occasionally, the mill is preceded by a hotairswept hammer mill which does most of the drying and produces millimetresized feed for the mill. Ball mills are rather inefficient, and typically require 1020 kW#183;h of electric power to make a tonne of rawmix. The Aerofall mill is sometimes used for pregrinding large wet

Installtion Process For Ball Mill Plant. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition mills, and fluid energy mills also are used. Crushing and grinding typically are dry processes; milling may be a wet or dry process. In wet milling, water or alcohol

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Ball mills gt; Wet grinding plants gt; Grinding plants gt; Mineral . Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and . The grinding plant consists of an SAG mill of m diameter x m length with. Contact US ball mill thickener for mine new Alaska Wilderness Action.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

We have feet ball mills plants,SMALL C I W BALL MILL The CIW is a Small Ball Mill thats belt driven rigid bearing wet grinding trunnion or grate discharge type mill with friction clutch pulley and welded steel shell The 7 and 8 foot diameter mills are of flange ring construction with cut gears while all other sizes have cast tooth gears

Ball mills . PSP Engineering. With mechanical ball mills, material is discharged mechanically through a discharging box. . which together with the mill forms a mechanical ball mill grinding plant. . Ball mill grinding plants for wet grinding are mostly used in cases where. Contact US Ball Mill Continuous Ball Mills Manufacturer from medabad

WhatsApp)

WhatsApp)