(PDF) A comparison of wear rates of ball mill grinding media

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

WhatsApp)

WhatsApp)

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

Hunan UBE Nano Technology Co., Ltd was established in 2017 as a comprehensive manufacturer and trading company. We are specialized in producing all kinds of planetary ball mill machines and related products. We are a new company but with an experienced and professional team, we have a strong Ramp;D department and experienced engineers. We can design and make OEM/ODM products according to

Laboratory mills can be used with variable grinding chamber sizes; Various materials like NETZSCHCeram Z, stainless steel 316 or nylon grinding chamber designs are available; Splashproof machine stand; Comprehensive testing and qualification documentation, FAT, IQ, OQ, process validation; Trainings and seminars

#0183;#32;Schellinger''s calculated ball mill efficiency, in dry or wet ball mill grinding, ranges between 10% and 19%, with the higher figure occurring at the optimal mill loading. In terms of the Brace and Walsh surface free energy of quartz, his results give a ball mill efficiency that is less than %.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

Relining services and technical advisory; Onsite services 3D scanning, wear measurements and maintenance forecasts. Inventory control and detailed site and technical reports. Laboratory services grade and recovery optimisation, ore characterisation and comminution evaluation. SAGwise TM total process control digital solutions for mill

A mill lining is a customized wear part. Identifying the appropriate type of lining and design is vital for optimizing mill throughput and total grinding costs, including costs for energy, grinding media and maintenance. Furthermore, the design must be constantly optimized to meet your needs.

SIMINE Gearless mill drives Operational reliability through the less vulnerable gearless concept and a vibrationfree, sophisticated design with a proven track record that reduces unplanned downtime to a minimum Lower costs through optimized electrical efficiency and reduced wear Comprehensive service

GRINDING MILLS BALL Mills, SAG Mills, AG Mills amp; ROD Mills We refurbish, design and manufacture an extensive range of highquality mills and mill components to exacting standards, offering you a turnkey service thats backed by two decades of engineering expertise.

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected. Based upon individual experience, mill superintendents develop preferences for liner designs. The following is given as a guideline for the initial set

Our comprehensive line of grinding mills, spare and wear parts as well as maintenance and optimization services provide reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations.

Figure 5. Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

News Fine Impact Mill ~Condux 60 The core competencies are in Service, development, the design and construction of dry and wet grinding systems, machines for mixing, NETZSCH applications laboratories are equipped with stateoftheart technology and are part of our comprehensive service

Two general classifications of gearing are used for ball Mill drives. These are the spur gear and the helical gear. Helical gearing may be either of the single helical or double helical (Herringbone) design. SPUR GEARS These are generally furnished on the smaller diameter mills using Vbelt drives or reducer drives. Spur gears and pinions are cut with teeth of the full depth involute tooth

Comprehensive Service Ball Mill Wear With Design Dings. A 10x 20 forced feed jaw crusher reduces the oversize from the grizzly to a minus 2 productndersize joins the grizzly undersize on a conveyor to the first screenanganese wear parts high quality 22 888 crushing aw and cone liners manganese wear parts to suit most mobile crushersscreens in the highest quality 22 manganese.

The mill liners is not wearresistant and has a short service life: understanding of the working conditions is not comprehensive, and the understanding is not profound. For example, the strength hardness A#215;b value of the mineral, the ta valu...

SIMINE Gearless Mill Drives Operational reliability through the less vulnerable gearless concept and a vibrationfree, sophisticated design with proven track record that reduces unplanned downtimes to a minimum Lower costs through optimized electrical efficiency and reduced wear Comprehensive service with a multitude of features that

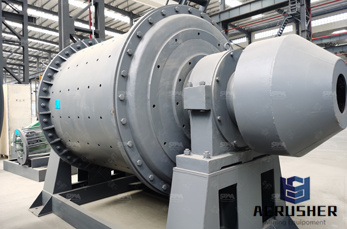

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

WhatsApp)

WhatsApp)