Iron Ore Dry Grinding Close Circuit Systems

Iron ore mining, iron ore mining The ball mill will operate with a cyclone cluster in a closed circuit. with the mines orehandling systems capable of Click amp; Chat Now

WhatsApp)

WhatsApp)

Iron ore mining, iron ore mining The ball mill will operate with a cyclone cluster in a closed circuit. with the mines orehandling systems capable of Click amp; Chat Now

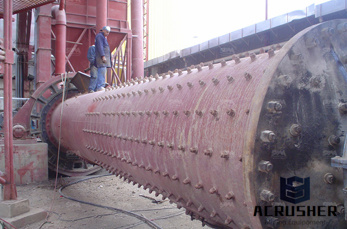

It was initially developed for relatively coarse grinding, but by using it in closed circuit with a classifier its use has been extended for fine grinding. Ball mills have shells of cast iron or steel plates and are carried on hollow trunnions.

Survey campaigns were carried out in both Samarco Minera#231;#227;o industrial plants,, Concentrator I and Concentrator II. The former is equipped with a reverseconfigured ball mill closed grinding circuit, while the latter is equipped with ball mills under a direct closed circuit.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice. In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less still.

Flotation copper closed circuit test . The closedcircuit process of 1 rough, 1 sweep and 3 concentrated ore returning in sequence is adopted to obtain a copper concentrate with a copper grade of % and a recovery rate of %. Iron beneficiation from copper tailings

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG

The circuit comprises a SAG mill, 12 m diameter by m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones. The SAG mill is fitted with a 20 MW gearless drive motor with bidirectional rotational capacity.

With these ores, there is significant cost associated with milling the ore to fine sizes using ball mills in closed circuit with hydrocyclones.

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill. Compared with grid type ball mill, overflow type ball mill can grind materials

Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65

It has been recognized that the grindability of an ore in a ball mill is a function of both feed and mill parameters Cast iron B = The factor CF is the correction for non standard conditions including wet open circuit wet closed circuit wet and dry grinding

Ball mill for iron ore grinding in Malaysia For both opencircuit and closedcircuit plant, you can choose our ball mill for powder grinding. Generally a ball mill grinds ores and other materials to a typical product size of 35 mesh or finer.

Iron ore mining process With fine ore particles it is more efficient to upgrade iron ore Wet ball mill and fine ore crushers are used during this process Spiral classification Tow stage spiral classification of close circuit is conducted with second ball mill grinding after the second classification . Sales Online

Close Circuit. In the above circuits, material is fed from hoppers to ball mill for reducing the size to microns. In closed circuit, micro particles are fed to classifier for segregation of desired material (based on its size) and rejected one is once again passed through ball mill. Whereas in open circuit, segregation through classifier is not considered.

Grinding systems are either open circuit or closed circuit. In an open circuit system, the feeding rate of clinker is adjusted to achieve the desired granularity of the product at the mill exit. In a closed circuit system, coarse particles are separated from the finer product and returned for a further grinding.

Beneficiation of Iron Ore Mineral ProcessingCrushing and GrindingHydroclassification and Magnetic FinishingConditioning and FlotationSilica Flotation ReagentsTh high capacity close circuit ball mill for iron ore. Home; product; high capacity close circuit ball mill for iron ore; product list. K Series Mobile Crushing Plant; Mobile Vibrating

WhatsApp)

WhatsApp)