McLellan Industries Mill Liner Handlers SD YouTube

Feb 06, 2017#0183;#32;Introduction to McLellan Mil Line Machines and McLellan Industries Inc.

WhatsApp)

WhatsApp)

Feb 06, 2017#0183;#32;Introduction to McLellan Mil Line Machines and McLellan Industries Inc.

A mill liner handler device for operating inside of a rotary mill having interior surface liner sections and being rotatable about an elongated longitudinal central axis and having a central door opening of smaller size than the mill cross section at one end thereof, said handler device comprising removable track means extending in longitudinal direction in the interior of said mill and

https://

Sep 10, 2014#0183;#32;McLellan mill relining systems deliver faster and safer mill liner installations.

Mill Liner Handler. Reliable, durable, and dependable construction allows for reliable service during critical, costly downtime. McLellan Designed Mill Liner Handlers are designed to be user friendly. Our main frame welded tubular steel chassis has mounting provisions for the moving of horizontal beam rollers, transpiration controls, hold down clamps, four lift eyes for lifting the entire unit by overhead

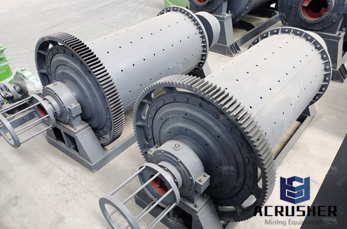

RME What is a Mill Liner Handler? SAG, Ball and Rod mills throughout the hard rock mining regions of the world. For liners larger than 1500kg, Mill Relining Machines are required.

With Metsos unique attachment system, liner bolts are inserted and removed from the outside of the mill. So, there is no need for any member of the installation crew to be in the dangerzone of the liners while inserting or removing liner bolts. The liner handler operator can simply position the liners

STEEL INDUSTRY IN IRAN. In 1927, plans were drawn up to establish smelting works in the north of the country to produce rail tracks domestically. This action was in connection with the goead given by the parliament (Majles) to start the construction of a railway between or Mus and of the railway budget, million tomns were earmarked for this purpose, and a German

A Mill Liner Handler is a purpose designed machine used to remove . RME''s Mill Liner Handlers find appliion in AG, SAG, Ball and Rod mills throughout the hard rock . Read more

The mill liner handler features a horizontal main beam that delivers replacement liners through the trunnion safely and quickly to a 3 axis powered liner manipulator. Reliable, durable, and dependable construction allows for reliable service during critical, costly built and engineered for your needs, our product will become an essential element to your milling process.

The Mill Liner Handler features a horizontal beam that delivers replacement liners through the trunnion safely and quickly. Once inside the mill, the liner is delivered to a 4 axis power liner manipulator. construction allows for servicReliable, durable and robust e during critical, costly downtime. Learn More.

Manufacturing Machine liner Handler MEH1000 model for ball mill #216; 18 ''x '' long, with wristgrip. Capacity of 1,000 kgs. 2000. Client: Svedala (Cajar Ferro) Brazil. Machine Design and Manufacturing Handler Liners MEH1000 model for ball mill #216; 20 ''x '' long. Capacity 2000.

The mill liner handler is a selfpropelled mobile structure on rails or wheels. Mill Liner Handlers are made to operate from 200 kg. Up to 5,000 kg. Other sizes on request. Power for the movement of the telpic arm and propulsion is provided by a central hydraulic structure on the installed base.

The centrepiece of RME''s Mill Relining System is the RUSSELL 7 Mill Relining Machine or RUSSELL 8 Mill Relining Machine. Available in maximum liner capacities from 500kg to 8000kg, these machines represent the ultimate in new liner replacement capability. Mill Relining Machines, with a grapple option to hold and precisely place liners exactly into the location for which they are intended, greatly reduces the manual aspects of mill relining, and increases liner replacement

There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball mills working as the secondary portion of a grinding circuit will utilize the

A longer lasting mill liner means less downtime for maintenance or new liner installation. A mill liner that occupies less space allows increased volume within the mill and leads to greater grinding capacity and throughput potential. Safer maintenance. 50% lighter and have 50% fewer parts on average when compared to traditional cast steel liners.

Design and manufacture of Liner Handler Machines for SAG mill #216; 30''x 14''de long, with wristgrip. Capacity 2000 kg : 2009. Client: Codelco Chuquicamata CHILE. Manufacture of Liner Handler Machines of feathers with two booms, for SAG mill #216; 32''x 15 ''long, with wristgrip. Capacity 3000 kg each boom. 2009 Client: RIO MINAS BRAZIL.

The Maxitool Mining team have extensive mill relining expertise with a combined experience approaching 6070 years. In recent times Maxitool has been heavily involved in overseas projects as well as domestically, with contracts expanding into Papua New Guinea and Indonesia and a heavy focus on business development in Asia. In 2014 we introduced our Jakarta based Business Development

#0183;#32;McLellan Mill Liner Handler Fast and Efficient Duration: 6:10. McLellan Industries, Inc. 8,518 views. 6:10. Brokk 160 renovando el quot;linerquot; interno de un molino de bolas Duration: 9:43.

There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball mills working as the secondary portion of a grinding circuit will utilize the

WhatsApp)

WhatsApp)