(PDF) Cement plant operation handbook | jorge pinedo

is a platform for academics to share research papers.

WhatsApp)

WhatsApp)

is a platform for academics to share research papers.

The Cement Plant Operations Handbook Philip A The Cement Plant Operations Handbook Philip A Alsop download BOK Download books for free Find books Cement P

plant species, it is reasonable to expect that the increasing environmental protection requirements will necessitate changes in how many maintenance activities are performed. Many resources are available to assist maintenance personnel in conducting maintenance activities in compliance with environmental requirements. Several environmental

May 27, 2016#0183;#32;cementplantoperationhandbook 1. TERNATIONAL Revieww July 1998 Philip A Alsop CEMENT I_ A NI 1 OPERATIONS HANDBOOK 1 Second Edition The concise guide to cement manufacture I FA E. 2. CEMENT PLANT OPERATIONS HANDBOOK For Dry Process Plants Philip A Alsop, PhD Second Edition July 1998 Tradeship Publications Ltd 3.

3. Prioritize assets within the plant. 4. Define maintenance requirements. 5. Allocate personnel resources. 6. Deploy tools (technology and/or software). 7. Measure success and continuously improve. These actions serve as the building blocks to redefine the plants maintenance program and to help build a sustainable

Examples are given to familiarize the reader with the usefulness of these formulas. The book can be used as a text manual for courses in cement technology, and as a reference for solving operating problems. The book is equally valuable for the manager supervisor, chemist, and operator as it is to the cement plant engineer. Show less

High Industry Approval. Since its launch in early 2005, CemNet eLearning has been used by thousands of students worldwide. Such personel training has been taken up by multinationals including Lafarge, Holcim, Cemex and HeidelbergCement through to major companies such as Titan, Buzzi Unicem, Siam Cement, Yanbu Cement, Egyptian Cement, Vassilliko, JK.

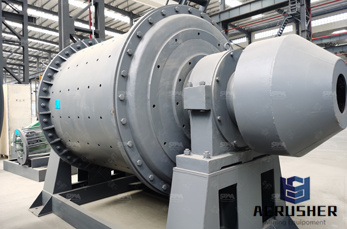

Cement milling 110 111 The Cement Plant Operations Handbook Seventh Edition 6. Cement milling Finish milling is the grinding together of clinker with some 35 per cent gypsum, natural or synthetic, for set control, and quite often other components: blastfurnace slag, pozzolan, silica fume, limestone or pulverised fuel ash (pfa

Jul 24, 2016#183; Cement Plant Operations Handbook 37 0 2 hours continuous 2 4 hours 1/4 turn every 15 minutes 4 12 hours 1/4 turn every hour Discharge 1D 7085% alumina 8 months 1D8D Basic, dolomite, or spinel 610months 8D 10D 70% alumina 21 months 10D feed end 40% alumina 2137 months D =

Maintenance factor The initial value multiplied by the maintenance factor gives the illuminance maintenance value. The maintenance factor can be determined individually, and takes the installations reduction in luminous flux caused by soiling and ageing of lamps, luminaires and room surfaces into account. The maintenance schedule (the cleaning

The essential reference for cement producers. Fully updated in 2019 and extended with a new alternative fuels section, the Seventh Edition of the Cement Plant Operations Handbook is now available free of charge to International Cement Review subscribers.. Covering some 340 pages, the cement industrys favourite technical reference book provides indepth information of the various aspects of

PDF Cement Plant Operation Handbook Free Download PDF. Download Cement Plant Operation Handbook Free in pdf format. Sponsored Ads. Account Login. Register. Search. Search. About Us We believe everything in the internet must be free. So this tool was designed for free download documents from the internet. Legal Notice. Cement.

Portland Cement Association. 5420 Old Orchard Road; Skokie, Illinois ; ; 200 Massachusetts Ave NW, Suite 200; Washington, 20001

Refractory Engineering And Kiln Maintenance In Cement Plants written by Saxena and has been published by CRC Press this book supported file pdf, txt, epub, kindle and other format this book has been release on with Technology amp; Engineering categories.

Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement industrys favourite technical reference book offers indepth information on the various aspects of cement production.

Handbook for Designing Cement Plants By Deolalkar Pdf, Qualified Engineer with a penchant need toUnderstand the intricacies of both Design and Developments in Engineering in Cement Machinery, Besides gaining hands on experience in Operation amp; Maintenance of this Machinery in I had the Fantastic chance of rubbing shoulders with Deolalkar at every point of His illusus career

SAP Plant Maintenance (SAP PM) is a software product that manages all maintenance activities in an organization. Plant Maintenance module consists of key activities to include inspection, notifications, corrective and preventive maintenance, repairs, and other measures to

Cement Plant Operations Handbook 5th Edition 16 SAMPLE 7. Maintenance 115 1. Failure Modes 2. Computerised Maintenance Management Systems 3. ReliabilityCentred Maintenance 4. Maintenance Cost Management 5. Maintenance Organisation 6. Role, Planning and Control 7. Mobile Equipment Maintenance 8. Environment and Pollution

The Cement Plant Operations Handbook for dry process plant by Philip A Alsop, PhD. Covering some 232 pages, the cement industrys favorite technical reference book provides indepth information on the various aspects of cement production plant from raw material extraction to the finished product. Key sections covering burning, grinding and quality control are supported by

Join the community and register for a free guest account to post a reply. 1156 posts. Time Posted 22/08/2006 10:21:23. admin says. Re: Maintenance. There is a difference between mean time between failures and mean time between stops. Best practice for kiln MTBF in the cement industry is in excess of 750 hours, while MTBS is somewhat shorter

Reliability Maintenance 386 Preventive maintenance 387 Predictive maintenance 390 Project maintenance 393 Improved Work Processes 396 Maintenance Metrics 397 Summary 403 Appendix B. The People Side of Planning 405 The People Rules of Planning 406 Rule 1:The planning program is not trying to give away the plant''s work to contractors 406 Contents xi

WhatsApp)

WhatsApp)