Cement Plant Machinery Walchandnagar Industries

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad.

WhatsApp)

WhatsApp)

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad.

Cement consumption is dependent on the time of year and prevalent weather conditions. Nearly twothirds of cement consumption occurs in the six months between May and October. The seasonal nature of the industry can result in large swings in cement and clinker (unfinished raw material) inventories at cement plants over the course of a year.

Like industries from aviation to financial services, the cement business has been on a big is beautiful march over the past five decades. A rush of expansions, mergers, acquisitions, and consolidations has reshaped the industry. The model has not necessarily created value for companies or their investors.

Een machine (leenwoord van het Franse machine, van Latijnse machina, van Griekse mechan#233; ofwel quot;werktuig, kunstmatige voorzieningquot;) is een apparaat opgebouwd uit een frame, een aandrijvingsmechanisme en overige specifieke onderdelen. Het is een mechanisme dat een vorm van beweging of energie in een andere vorm van beweging of energie kan omzetten.

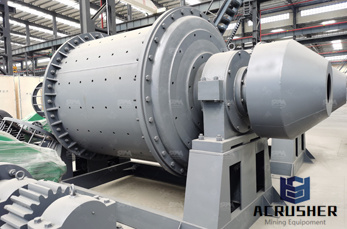

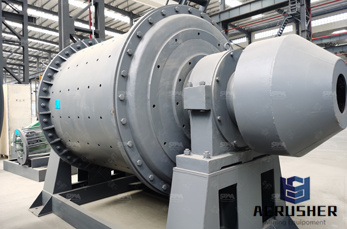

Dat Machine In Cement Industry. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

dat machine in cement industry. I want to set up a cement industry. What are the basic . Jul 03, 2015 #183; I am assuming you intend to establish a cement manufacturing mill/plant, and be a part of the larger industry. You don''t set up a Industry. On that note, starting a cement manufacturing business requires serious time, energy, and capital

#0183;#32;Industry digital innovations, from advanced data analytics to intelligent networks, offer tremendous opportunity to create value and raise the efficiency of production processes. Yet few cement producers have implemented advances in any systematic way.

The good news is that processindustry plants are routinely capturing and storing vast amounts of machine data that they can readily mine to create algorithms. This means that although they may have fallen behind on the technological front, with guidance from external experts and interim external resources as a bridge, cement plants and manufacturers with heavy assets can quickly catch up.

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications. The most common way to manufacture portland cement is through a dry method.

As a pioneer in digitalisation in the cement industry, we have developed digital solutions for equipment control, process optimisation and plant optimisation since digital technologies were first introduced into industrial production processes.

Tanzanias cement production amounted to million tonnes in 2018, compared to million tonnes in 2014, representing an increase of 61%. The Tanzania Portland Cement Company (TPCC) is the leading company in Tanzanias cement industry, holding 36% of the market share.

Cement (Frans: ciment, ontleend aan het Latijnse caementum, uwen steen of steenslag) is een hydraulisch bindmiddel, dat wil zeggen verhardend door een chemische reactie met, dat voornamelijk uit calciumwaterstofsilicaat bestaat, is een fijngemalen materiaal dat na mengen met water een plastische massa vormt, die zowel onder water als in de buitenlucht verhardt tot een

Industrie. Beton en cement. Houd uw fabriek schoon en minimaliseer stilstand. Zou er een omgeving bestaan waar machines het zwaarder hebben dan de beton en cementsector? Toch gaan ze maar 2 tot 3 maanden mee, wat betekent dat de fabriek moet worden stilgelegd

Clinker grinding (cement mill), packing plant amp; Loading plant, quality control. It also provides the brief description about the machinery used in each stage and its working principles. Cement industry has come a long way in technological up gradation, production and quality. India today is the second largest cement

cement industry machines Cement Industry Equipment, Cement Industry, Alibaba. Alibaba offers 13,867 cement industry equipment products About 4% of these are concrete batching plant, 1% are other construction material making machinery, and 1% are other machinery amp; industry equipment A wide variety of cement industry equipment options are available to you, such

The RHI Training Center Opens for Cement Customers RHI AG. personnel, customers from the cement industry can learn in opportunities with the DAT lining machinea standard device used on

#0183;#32;Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

Industrial Filtration for the Cement Industry Cement consists of very hard and abrasive dust particles. Being very abrasive, this dust type rapidly wears out filter bags. To ensure the filters do not fail, frequent filter bag replacement is needed. Obviously, this equals frequent maintenance. Reduce Emissions and Maintenance with Pleated Bags By installing shorter filter

WhatsApp)

WhatsApp)