Ecofriendly Gold Leaching Reagents, Gold Dressing

CNFREE Ecofriendly gold leaching chemical is socalled nontoxic and cyanidefree gold dressing agent, which can replace sodium cyanide without changing the original equipment and cyanide process.

WhatsApp)

WhatsApp)

CNFREE Ecofriendly gold leaching chemical is socalled nontoxic and cyanidefree gold dressing agent, which can replace sodium cyanide without changing the original equipment and cyanide process.

The gold CIL process is mainly used in the oxide ore which has low grade of silver, its more economize and has more benefit . Process introduction CIL process is mainly include : decontaminate, concentrate before leaching, leaching and adsorption, desorption and electrowinning, hydrometallurgy, regeneration of activated carbon tailings filting, waste water treatement and so on .

Hot Selling Mineral Ore Processing Dressing Table,Best Choice For Heavy Minerals Separation, Find Complete Details about Hot Selling Mineral Ore Processing Dressing Table,Best Choice For Heavy Minerals Separation,Mineral Ore Dressing Table,Gold Ore Table Concentrator,Gold Dressing Shaking Table from Mineral Separator Supplier or ManufacturerJiangxi Jinshibao Mining Machinery

The general process of placer gold beneficiation is screeningjiggingshakermercury mixing. There are also local lowgrade placer gold beneficiation using chute as a rough separation equipment, jig as a sweeping equipment, amalgamation tube or shaker as a selection equipment.

The Miller process is rapid and simple, but it produces gold of only about percent purity. The Wohlwill process increases purity to about percent by electrolysis. In this process, a casting of impure gold is lowered into an electrolyte solution of hydrochloric acid and gold chloride.

Outlining best practices in gold processing from a variety of perspectives, Gold Ore Processing: Project Development and Operations is a musthave reference for anyone working in the gold industry, including metallurgists, geologists, chemists, mining engineers, and many others.

Of all the methods of extracting gold amp; processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery

Metallurgical ContentMilling History AmalgamationConcentration of MineralsBulk FlotationSelective FlotationFlotation of Nonmetallic MineralsOrder of Mineral FloatabilityLeaching by Cyanidation Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment charges. These charges varied with the type of ore

2. Ore Dressing Technology and Equipment. The selection of sand and gold mine is mainly based on the physical properties of minerals, such as grain size, shape and specific gravity, so as to achieve the purpose of sorting in the moving medium flow.

Gold Extraction Equipment. Carbon Screen; Zinc Powder Displacement Device; Desorption Electrolysis System; Mineral Processing EPC; Solutions; About; Contact; Home; Products; dressing process mineral processing plant low consumption; dressing process mineral processing plant low consumption. Efficient Thickener. Efficient Thickener

#0183;#32;Mineral Processing Jaw crusher gyratory Crusher beneficiaton roll crusher screening separation, increase the surface area available for next process liberate valuable minerals held within MASSIVE CRUSHERS IN MINERAL DRESSING. 26. 28 The best method to cause rapture in solid materials is the application of shearing loads

Gold Flotation Mineral Processing style laboratory ore flotation cell newstyle laboratory ore flotation cell design and operation characteristics cience directflotation machine style gold process production line equipmentun 17 2018 he versatile. ore dressing machine customized flotation cell for Mineral Processing Flowsheets.

HOT Mining owns dozens of experts with rich experience in mines and mineral processing design, mineral concentration,underground mining,mining,mineral preparation. Only experienced experts can offer more detailed engineering consultant for customer and let customer have enough knowledge to the coal washing plant and value of mines.

#0183;#32;Jigging Process Animation Mineral Processing https:// click on above link for more videos re...

Separating Process. Magnetic Separator; Sf Flotation Cell; Flotation Cell; gold dressing plant in mineral processing best sale; gold dressing plant in mineral processing best sale. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener.

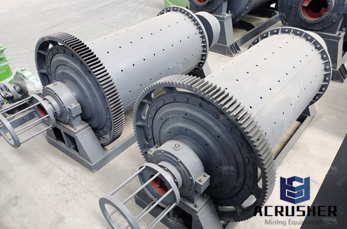

process of gold mineral processing technology best; process of gold mineral processing technology best. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump.

a gold concentrate that can be smelted down to a gold bullion. Amalgamating mills: Mexican arrastra, Chilean trapiche (p20). Flotation and subsequent processes (refractory ore processing) The flotation process is described in detail in chapter Native gold, gold tellurides, and

eral processing as follows: Mineral processing is the first step in the solid mineral extractive process. The goal is to produce granular material which meets a specific set of requirements in terms of material composition and physical characteristics (especially granulation). The minerals are then used either as

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate

WhatsApp)

WhatsApp)