Specification Of Steel Ball In Ball Mill

The grinding media is the balls, which may be made of steel (chrome steel), use in a ball mill, each material having its own specific properties and advantages. Read more Roller Ball Mill Glen Creston

WhatsApp)

WhatsApp)

The grinding media is the balls, which may be made of steel (chrome steel), use in a ball mill, each material having its own specific properties and advantages. Read more Roller Ball Mill Glen Creston

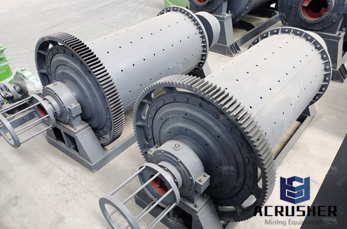

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

In a ball mill of diameter 2000mm, 100mm dia steel balls are being used for grinding, presently, for the materials being ground, the mill is run at 15 rpm. The speed at which mill will have to run if 100mm balls are replaced by50 mm balls, all the other conditions remaining the same

Ball mill Wikipedia

Forged steel balls are welcomed in different kinds of mines, like golden mines, copper mines etc. equipped with different size of ball mills.

Tolerance of the steel ball ranges from G100 to G500 depending upon the quality and performance specifications of the overall product. 2, 3, 4 and 5 mm or 3/32quot;, 1/8quot;, 5/32quot; and 3/16 inch diameter balls are generally used.

Ball milling is one of the few unit operations that actual improve in performance and efficiency with increasing size. The ABBE Slice Mill is the same as the product mill and can replicate all mill operating parameters but with very little product. Materials: Abrasion Resistant Steel, Stainless Steel, Polyurethane or Rubber Lined.

Ball Mill Specification / Ball Mill for Iron Ores / Grinding Steel Balls. China Ball Mill Specification / Ball Mill for Iron Ores / Grinding Steel Balls for Ball Mills, which may be made of steel (chrome steel), use in a ball mill, each material having its own specific properties and advantages. Read more. Roller Ball Mill Glen Creston.

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill

New and Used Ball Mills for Sale Ball Mill Supplier . The ball mill grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. There are many types of grinding media suitable for use in a ball mill, including ceramic balls, flint pebbles

F221515 Standard Specification for Balls, Bearings, Ferrous and Nonferrous for Use in (premium quality bearing steel or double vacuum melted M50), and Composition 14 (corrosion resisting unhardened steel). Ball samples shall be subjected to a series of tests in order to determine the following properties: density, hardness, fracture

Table of ContentsOptimum Size of BallsTests with Different Mixtures of Balls in Conical, Cylindrical, and Grid MillsClosedCircuit Grinding Several years ago, Davis assumed that the rate of wear of the different sizes of balls in a ball mill was directly proportional to the weight of each ball, and he evolved a formula for calculating a balanced charge. Operators have used this formula when

The best practice is to use the same material for balls and the grinding jar. However it is also common practice, in my opinion, to use quot;typicalquot; bearing steel balls with a hardened steel jar.

Steel mill balls specification patterson industries ball amp;amp; pebble mills. the construction of cylinders is the same as other patterson mills, but sizes are limited in steel ball models to 3''6quot; x 4''0quot; and, complete the ball and pebble mill specification sheet and submit by email or fax to patterson for quotation

The product specification can be designed according to the requirement of customers, and this product can be used in the filling of a ball mill or rod mill. Pay more attention to the craftsmanship, and the hardness and performance characteristics is also very important because the steel ball and steel section are the wearing parts.

However, not many high Cr balls are used in primary grinding because the improvement obtained in wear resistance relative to steel, typically 25 30%, is not enough to offset Its higher cost. In primary ball milling, wear speed is largely independent of ball diameter and mill volume.

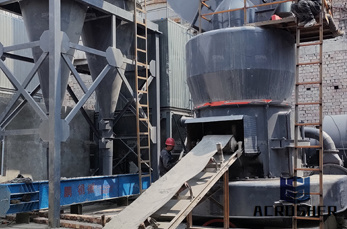

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber.

Home; Grinding balls for mining suitable for all mill applications. Grinding balls for mining are made from various metals such as steel, hard metal and, they are commonly manufactured from steel and steel alloys which have superior resistance to abrasion and low wear might be between 15 and 66 on the Rockwell Scale or between 85 to 105 on the Vickers hardness

FORGED STEEL BALLS LARGE DIAMETER Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications. They are made by machine (standard) sizes 20mm75mm. They are manually made (hit by air hammer) sizes 75mm125mm. They have hardness 5563 HRC.

WhatsApp)

WhatsApp)