Cement Manufacturing Process YouTube

#0183;#32;Lucky Cement Limited (LCL) is Pakistan''s largest producer and leading exporter of quality cement with the production capacity of tons per annum.

WhatsApp)

WhatsApp)

#0183;#32;Lucky Cement Limited (LCL) is Pakistan''s largest producer and leading exporter of quality cement with the production capacity of tons per annum.

The process out clinker is cooled and ground to a fine powder with the addition of about 3 to 5% of gypsum. The material produced by this process known as Portland cement. The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water.

#0183;#32;In this process a mixture of silica sand containing cement and water. When making the mold,the cement bonded sand mixture must be allowed to harden first,before the pattern is mold

Figure (5): The Wet process of cement (Masenan, 2008) Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and

Nccbm1 Ppt Presentation PowerPoint Presentations Online . nccbm1 ppt presentation process and decision making establish and upto raw grinding kiln and coal mill cement mill and packing various sections for #187;More detailed

Nccbm1 Ppt Presentation PowerPoint Presentations Online . nccbm1 ppt presentation process and decision making establish and upto raw grinding kiln and coal mill cement mill and packing various sections for #187;More detailed

cement making process ppt. The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes. Leave a Comment / ACADEMIC WRITING TASK 1 / By Jaspreet kaur / 29/04/2019 29/04/2019.

1. cement ppt SlideShare. Mar 31, 2015 1. cement ppt 1. Cement: Cement is the mixture of calcareous, siliceous, argillaceous and other substances. Cement is used as a binding material in mortar, concrete, etc. 2. Chemical Composition of cement is: Lime 63% Silica 22% Alumina 06% Iron oxide 03% Gypsum 01 to 04% Suchismita Su, Asst. Professor

THE CEMENT MANUFACTURING PROCESS Prof. Dr Elshafie med Gad Faculty of Applied Science Chemistry Dept. Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 26 % gypsum Raw Materials Necessary for Portland Cement

cementcement_manufacturing_ Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online.

cement. The white hot substance that exits the kiln, called clinker, is air cooled with the hot air returning to the kiln to conserve energy. The kiln production line is monitored and controlled by a sophisticated control system to continuously analyze and monitor every stage of the process.

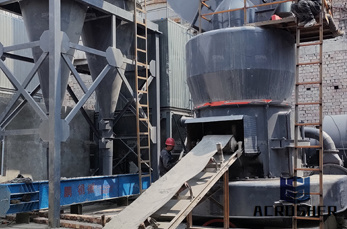

Homegt;gt;Knowledge Basegt;gt;Basic Process of Cement Manufacturing. Basic Process of Cement Manufacturing. Quarry. Crushing. Raw Mill

Cement Manufacturing Process Free Download (pdf,doc,xls,rtf,ppt . Found 43 files for cement manufacturing these results or try to change your search query. Manufacture of cement, Life process ppt, Life processes. #187;More detailed

The process out clinker is cooled and ground to a fine powder with the addition of about 3 to 5% of gypsum. The material produced by this process known as Portland cement. The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water.

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference. NOTE:

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

#0183;#32;Cement isused as a binding material inmortar, concrete, etc. 3. Chemical Composition ofcement is:Lime 63%Silica 22%Alumina 06%Iron oxide 03%Gypsum 01 to 04% 4. MANUFACTURING OF CEMENT:(1) Mixing and crushing of raw materialsa. Dry processb. Wet process

#0183;#32;Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

#0183;#32;Types of Cement Processes Wet Process. Dry Process 74% of cement produced. Preheater/Precalciner Process. 16. Evolution of the cement Process Wet process easiest to control chemistry amp; better for moist raw materials. Wet process high fuel requirements fuel needed to evaporate 30+% slurry water.

WhatsApp)

WhatsApp)