What is Cement Clinker? Composition, Types amp; Uses Civil

Cement clinker Wikipedia

WhatsApp)

WhatsApp)

Cement clinker Wikipedia

Grate coolers which represent one of the pyroprocessing units are extensively used in cement industries. The essential function of grate coolers is a waste heat recovery from hot clinker which

Preparation of cement. This stage completes the manufacturing process where clinker nodules are milled into cement. Following clinker milling, the cement is ready for use as a binder in various concrete mixes.

1. Clinker is a nodular material which is used as the binder in cement products. Cement is a binding agent that sets and hardens to adhere to building units such as stones, bricks, tiles etc. 2. Clinker is a granular substance containing spherical pellets of diameter 325 mm.

In cement industry raw mill exhaust fans handle ton of exhaust gases for the production of 1 ton of clinker. Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles.

#0183;#32; Cement production process. Cement is considered one of the most important building materials around the world. In 1995 the world production of cement was about 1420 million tonnes (Cembureau, 1997).Cement production is an energyintensive process consuming thermal energy of the order of GJ/tonne of clinker produced, which accounts for 30 40 percent of production costs

Clinker cooler monitoring. The clinker cooler is one of the most critical applications in cement production as the rate of cooling can be critical to the clinker quality and overall performance of cement.: Thanks to our comprehensive portfolio we can offer a whole clinker cooler monitoring package all from one source.

Portland cement clinker overview. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 #176;C 1500 #176;C. The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties. This page gives a thumbnail sketch.

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

Cement production was million tonnes in 201819, up 9 per cent over 201718. Increased cement production has been required to meet consistent demand . Cement imports were million tonnes in 201819, a drop of around 7 per cent compared to 201718 levels.

#0183;#32;The key difference between clinker and cement is that clinker appears as marblelike nodules, whereas cement is a very fine powder.. Earlier, people did not have sophisticated homes; therefore, they used simple things found in the environment to build houses. But today there are many advanced materials and equipment, which assist in constructions.

24 #183; The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding

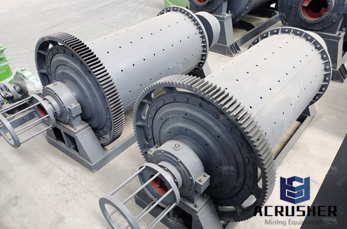

Used in the plant, limestone (5560%), marl (3540%), and copper slag (%) are used as cement raw materials for the production of clinker. The clinker is then finely ground in a ball mill grinding circuit together with a small amount (typically 4%) of gypsum to produce cement in the Turkey Trabzon Cement Plant ( Alp, Deveci, amp; S#252;ng#252;n, 2008 ).

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color. It is produced by heating limestone and clay to the point of liquefaction at about 1400#176;C1500#176;C in the rotary kiln.

Clinker Cooler, Cement Cooler, Grate Cooler Clinker . The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production The clinker cooler is mainly used to cool and transport the cement clinker At the same time, cement cooler also provide hotair for rotary kiln and calciner, it is the main equipment of heat recovery for burning system

Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules are formed. Clinker and gypsum (about 5 %) are mixed and finely milled to obtain cement. Gypsum control the setting properties of the cement.

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sand.

WhatsApp)

WhatsApp)