HighPerformance Roughing/Finishing Carbide Ball End

When it comes to HighPerformance Roughing/Finishing Carbide Ball End Mills, Grainger''s got your back. Easy online ordering for the ones who get it done

WhatsApp)

WhatsApp)

When it comes to HighPerformance Roughing/Finishing Carbide Ball End Mills, Grainger''s got your back. Easy online ordering for the ones who get it done

Power Transmission Pumps Raw Materials Safety TC 1/2x1/2x2x4 TiCN Ball Nose 4FL Center Cutting GP HSS Roughing Endmill. HSS end mills can be an effective alternative to carbide choices when conventional or slow spindle machines are used,

Center Cutting Roughing Cobalt End Mills; Carbide End Mills. MultiPurpose Carbide End Mills. 2 Flute Single End Center Cutting Carbide End Mill; 2 Flute Single End Ball Center Cutting Carbide End Mill; Metric 2 Flute Single End Center Cutting Carbide End Mill; 4 Flute Single End Center Cutting Carbide End Mill; 4 Flute Single End Corner Radius

Ball nose end mills are used on workpieces with complex surfaces. Choosing flat end mill vs. a ball end mill will determine the characteristics of the tooling marks (or lack thereof) on your model. Most jobs will benefit from strategic use of multiple size and shape tools for milling different features. End Mills are often used for roughing and

Operation: Roughing (side amp; tip)Material: 4140 steel, Rc 2430Tool: 1BW7VR01Diameter: .75quot;Effective: 2 (cutting edges)Insert: NKET180300RExtension fr...

In the images below well use a stepover equal to 1/10, 1/5, and 1/3 of the tool diameter to show this correlation. To put real numbers on this, that would be equavalent to a .012, .025, and .042 stepover for a .125 ball mill. Stepover =1/10 of diameter. Stepover =1/5 of diameter. Stepover =1/3 of diameter

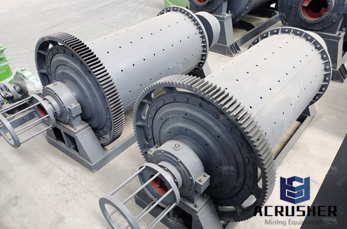

centre transmission ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals. centre transmission ball mill

#0183;#32;Face Mills. End Mills. Inserts. Plunge Mills. Slotters. Solid Milling. View All Solid Milling Tools Economical 2Sided Inserts amp; Maximum Roughing Productivity. Jul 09, 2020. Solid Carbide Guide Pads for Deep Drills. Home gt; Milling gt; Indexable Milling gt; Indexable Mills gt; End Mills gt; Ball Nose View Filters. Filter Your Results

Searching for 3/16quot; General Purpose Roughing/Finishing Carbide Ball End Mills? Grainger''s got your back. Easy online ordering for the ones who get it done

Distributor of end mills including roughing end mills made from cobalt. Specifications of roughing end mills include 1 1/2 in. maximum size, 1 1/2 in. maximum shank dia., 2 in. maximum length of cut amp; 4 1/2 in. maximum overall length. Roughing end mills are available with ball ends amp; suitable for center cutting, profiling amp; slotting applications.

#0183;#32;Roughing end mills quickly remove large amounts of material. This kind of end mill utilizes a wavy tooth form cut on the periphery. These wavy teeth form many successive cutting edges producing many small chips, resulting in a relatively rough surface finish.

Center holes at both ends enables a user to resharpen the end mill by grinding the face of the flute without distorting the roughing form. More on this Product Distributors Order Online Center Cutting Three Flute High Helix for Aluminum Roughing Cobalt End Mills

Roughing mill rolling of reheated slab: The roughing mill usually consists of one or two roughing stands in which the slab is hot rolled back and forth 5 or 7 times repeatedly to reach the minimum thickness requirement. The roughing mill also contains edger rolls that are used to roll the edge of slab and center it.

centre transmission ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals. centre transmission ball mill

Several types of ball mill drives can be furnished, made up of various combinations of gearing, motors and transmission equipment. The correct combination to be selected takes into consideration power requirements, gear ratings, floor space, interference from other plant equipment and motor characteristics. The main types are described and illustrated on these pages. Motors considered are

WhatsApp)

WhatsApp)