(PDF) Costing of the production and delivery of readymix

Jan 16, 2016#0183;#32;The paper presents a model for costing production and transportation of readymixconcrete (RMC) based on type of the mix and customer site information.

WhatsApp)

WhatsApp)

Jan 16, 2016#0183;#32;The paper presents a model for costing production and transportation of readymixconcrete (RMC) based on type of the mix and customer site information.

Cement manufacturing (Portland cement and ecocement) Readymix concreate production (conventional and green readymix concreate) Lifecycle costing model and assessment method The LCC analysis in FISSAC was made using productbased comparisons. The results of this comparative

mathematical model of cement production is develope d, which minimizes the Life Cycle Cost (LCC) of the cement plant, while satisfy ing the forecasted demand and various constraints. The economicmathematical model, developed in this research, is useful for existing cement plants and for those that will be built in the future.

In Nigeria, approximately 40 to 50 per cent of cement manufacturing cost is energy related; each tonne of ce ment requires 60 130 kg of fuel oil or its equivalent and about 105 kWh of electricity, depending on the cement variety and process type employed [10]. Cement produc tion spreads across five geopolitical zones due to the

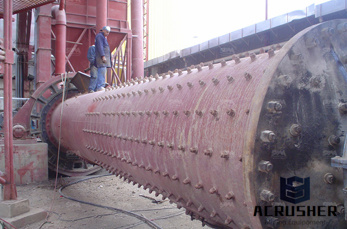

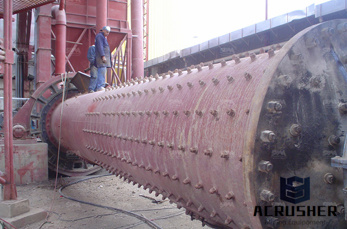

Cement Plant Costing Standardsrotary Kiln . Cement Manufacturing Process Phases Flow Chart Aug 30 2012 generally cement plants are fixed where the quarry of limestone is near bye this saves the extra fuel cost and makes cement somehow economical raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant there are also various other raw

Nov 13, 2019#0183;#32;Standard costing Standard costing is one of the most common costing methodologies employed by manufacturing operations. Standard costing methodology requires manufacturers to establish standard rates for materials and labor that are used in production and/or inventory costing.

Standard costing is an important subtopic of cost accounting. Standard costs are usually associated with a manufacturing company''s costs of direct material, direct labor, and manufacturing overhead. Standard costs are usually associated with a manufacturing company''s costs of direct material, direct labor, and manufacturing overhead.

Aug 09, 2014#0183;#32;4. Cement mill From the conveying system of Clinker silo, to cement mill proper until Cement Silos. 5. Packing This include all the flow clain and bucket elevator from Cement Silo until the rotopacker. Fixed cost are normally includes the Maintenance stock,

Manufacturing cost models are a custom easytouse formula based method of creating a manufacturing process. Once created, using the embedded model editor, these models have inputs or drop down lists, as well as formulas that quickly and easily complete calculations for manufacturing

Methods of Costing In Manufacturing Organisations: Specific Order Costing and Operations Costing. In manufacturing organisations, the principles of cost accumulation and their identification with products are more clear and visible and therefore the principles used by a manufacturing enterprise is often used by other organisations also for accumulating costs.

Cement Industry (Cost Accounting Records), Order 1994. (2) This Order shall apply to every company engaged in production, processing and manufacturing of clinker or cement or both. (3) It shall come into force on such date as the Corporate Law Authority may, by Notification in the official Gazette, appoint. 2.

Nov 18, 2020#0183;#32;Under this model, companies must identify the activities that drive costs, the total direct materials and labor needed to complete production activities and the cost driver for applying manufacturing overhead (indirect production costs). Through this model, companies can accurately identify how they can allocate production costs to products from every activity within the company.

COST ACCOUNTING RECORDS (CEMENT) RULES, 1997 (As amended upto June, 2004) Ministry of Finance (Depar tment of Company Affairs) NOTIFICA TION New Delhi, the 1 1th September, 1997 536(E) In exercise of powers conferred by subsection (I) of section 642, read with

Sep 24, 2017#0183;#32;There are two conventional costing approaches used in manufacturing, namely process and job order costing. Process costing method analyzes the net cost of a manufacturing process. Since most manufacturing processes involve more than one step, calculation is made for each step to arrive at a unit cost average for the entire production system.

In this method the total cost is divided by the number of units produced to ascertain cost per unit and it is applied in industries like collieries, quarries, bricks works, oil drilling, paper mills, flour mills, cement manufacturing, textile mills, etc.

Costing methods for manufacturing are accounting techniques that are used to help understand the value of inputs and outputs in a production process. The right product costing methods in manufacturing helps to make informed decisions about production levels, pricing, competitive strategy, future investment, and a host of other concerns.

Standard costing is most applicable for a company with stable costs and little cost variance from one manufacturing run to another. Companies with minimal accounting staff often use standard cost accounting. With standard costing, you estimate costs for each end item assembly and manufactured part on a levelbylevel basis before production begins.

The cement industry relies on power. Power and fuel costs account for ~30% of the price of cement when it''s sold. As a result, power and fuel have a major impact on the company''s operating

ERP for cement manufacturing (1) ERP software industry (1) ERP solution (1) ERP systems (1) EU (1) Electronic Flight Bag (1) Employment Laws (1) In the warehousing space, the costing model differs according to a customers needs and there will be a varied set of requirements for every customer which includes the type of facility (shared

Costing Methods and Important Costing Terms. Sep 24, 2017 It is also called the single output costing. It is used in costing of products that are expressed in identical units and suitable for products that are manufactured by continuous activity. Example: Cement manufacturing, Dairy, Mining etc. Job costing:

The paper presents a model for costing RMC based on the type of mix and customers information. The model divides the cost into onfloor, delivery, waste riding, and penalties related cost. The model utilizes ABC to identify activities and assign cost of resources products according to the actual consumption of each product from recourses.

The second major component in the production of cement is the cost of raw materials. The primary raw material thats used is limestone. Raw materials account for 30%40% of the cost of sales.

WhatsApp)

WhatsApp)