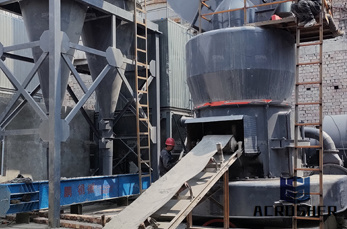

China High Efficient Ball Mill Grinding Machine Photos

High Efficient Ball Mill Grinding Machine picture from Yantai Fulin Mining Machinery Co., Ltd. view photo of Ball Mill Price, Grinding Machine, Mining China Suppliers for

WhatsApp)

WhatsApp)

High Efficient Ball Mill Grinding Machine picture from Yantai Fulin Mining Machinery Co., Ltd. view photo of Ball Mill Price, Grinding Machine, Mining China Suppliers for

These ball profile end mills are engineered for excellent performance in light profiling, High Efficiency Milling (HEM), and . . . 6 Flute Corner Radius Variable Pitch Reduced Neck The reduced neck geometry of this variable pitch end mill with 6 flutes provides maximum strength in

High Efficiency Ball Mill From Zk Manufacture Company picture from Henan Zhengzhou Mining Machinery Co., Ltd. view photo of Ball Mill, Ball Mill for Ores, Mill China Suppliers for More Products and Price.

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term quot;ball millsquot; is often used in place of the terms quot;stirred ball millsquot; or quot;Attritors,quot; but the differences between the types of mills are quite distinct.

Ball Mill with High Grinding Efficiency picture from CITICHL HEAVY INDUSTRIES CO., LTD. view photo of Ball Mill, Mill, Grinding Ball China Suppliers for More Products and Price.

The terms highspeed vibration milling (HSVM), highspeed ball milling (HSBM), and planetary ball mill (PBM) are often used. The commercial apparatus are PBMs Fritsch P5 and Fritsch Pulverisettes 6 and 7 classic line, the Retsch shaker (or mixer) mills ZM1, MM200, MM400, AS200, the Spex 8000, 6750 freezer/mill SPEX CertiPrep, and the vibrational ball mill.

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account. As well, mills with different

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

Highefficiency Ball Mill : Shicheng Oasis Mineral Equipment Manufacturing Co., The rotation big gearwheel is made by cast hobbling processing and the drum is equipped with wearresistant liner, which has good wearresistance. The machine is with stable and reliable working condition.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

offers 1,835 ball mill drum products. A wide variety of ball mill drum options are available to you, such as material.

In highenergy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber. Highenergy mills are classified into attrition ball mills, planetary ball mills, vibrating ball mills, and lowenergy tumbling mills. In highenergy ball milling, formation of ceramic nanoreinforcement by in situ reaction is possible.

#0183;#32;High Efficiency Milling Defined HEM is a milling technique for roughing that utilizes a lower Radial Depth of Cut (RDOC) and a higher Axial Depth of Cut (ADOC). This spreads wear evenly across the cutting edge, dissipates heat, and reduces the chance of tool failure.

High Efficiency Mineral Stone Grinding Ball Mill Machine,Ball Mill For Aluminum Powder,Mineral Stone Grinding Ball Mill, Find Complete Details about High Efficiency

Planetary mills At present planetary mills of high accelerations providing fast and efficient milling of various materials on industrial scale are commercially available in Russia.. The principle of planetary mills performance. Planetary mills are usually provided with 3 or 4 jars (drums) rotating around the central axis and simultaneously around their own axes in the opposite direction (like

Productivity mills with smooth lining less than productivity mills with ribbed liner. Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by high

#0183;#32;High performance end mills designed to achieve higher speeds and feeds will help machinists to reap the full benefits of this popular machining method. High Efficiency Milling Defined. HEM is a milling technique for roughing that utilizes a lower Radial Depth of Cut (RDOC) and a higher Axial Depth of Cut (ADOC).

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term quot;ball millsquot; is often used in place of the terms quot;stirred ball millsquot; or quot;Attritors,quot; but the differences between the types of mills are quite distinct.

WhatsApp)

WhatsApp)