Small Size Ball Mill for Zircon Sand Grinding YouTube

#0183;#32;Various Stone Crusher Machine For Sale,Stone crusher, mineral grinding machine, sand making machine, mobile crushing plant, processing equipment through

WhatsApp)

WhatsApp)

#0183;#32;Various Stone Crusher Machine For Sale,Stone crusher, mineral grinding machine, sand making machine, mobile crushing plant, processing equipment through

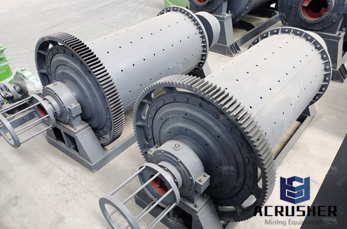

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Applications. Ball mills are found in settings as diverse as laboratories and mines, among others. Technologies. Ball mills can grind in either a wet or a dry environment.

The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions. Add to Quote request Category: Crushers, Pulverizers, Grinders

If you want a sturdy, compact machine that you wont have to break the bank to secure, the Klutch Mini Mill is just the one. This mini mill suited for light to medium duty tasks, with excellent performance. The machine has a #189; HP motor that uses a power input of 110 V. Thus, you can operate it at home, sourcing the power from your wall outlet.

Small production ball mill for ore grinding. This is a 3foot by 6foot continuous ball mill, and this machine will process one ton an hour at 65 mesh. You can actually process finer than that, down to about 200 mesh, but the throughput goes down.

Grinding Machine, Ball Mill, Copper Grinding Machine manufacturer / supplier in China, offering Large Capacity Grinding Ball Mill Machine for Copper Ore, Best Selling Professional Ut61A Handheld Mini Digital Multimeters, Log Washer Silica Sand Washing Machine Coal

DOVE offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing. Wide range of capacities DOVE offers variety of models with a wide range of capacities, applicable for laboratories (200 gr.

Small Processing Capacity Grinding Ball Mill Machine For Aluminium Powder Prices, Find Complete Details about Small Processing Capacity Grinding Ball Mill Machine For Aluminium Powder Prices,Ball Mill For Aluminium Powder,Mini Ball Mill Machine,Mini Ball Mill from Mine Mill Supplier or ManufacturerHenan Fote Heavy Machinery Co., Ltd.

to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit. Each of these performance parameters peaks at different filling values. In order to continuously optimize mill operation, it is vital to obtain regular measurements of the ball load and pulp position.

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

Sepors 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding mill.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Find the China Grinding Ball Mill, Find the best Grinding Ball Mill made in China, China Grinding Ball Mill Shopping Guide. Sourcing the right Grinding Ball Mill supplier can be timeconsuming and difficult. Buying Request Hub makes it simple, with just a few steps: post a Buying Request and when its approved, suppliers on our site can quote.

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

One machine that is heavily used for crushing and grinding tasks is the ball mill. This machine is described as a grinding device, capable to crush and transform large hard materials into fine powder.

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel.

offers 502 mini ball mill products. About 36% of these are Mine Mill, 0% are Flour Mill, and 24% are Grinding Equipment. A wide variety of mini ball mill options are available to you, such as condition, local service location, and applicable industries.

The Sunwin Mini Milling Machine currently goes for just over 200 bucks, making it one of the cheapest electric mills in the market. Its a small mill weighing in at just pounds. Therefore, if you need a portable mill that you can transport from place to place without a struggle, this is the one to buy.

Lab Sample Grinder Machine. Type: Sampling Machine Model Number: GJ3 Brand: TENCAN Applications: Sample grinder machine is also called sealed lab sample grinder machine, which is often used for milling, grinding, smashing nonmetallic minerals with certain hardness, such as coal, coke, waste rock, all kinds of ores. It grinds materials into powder for lab analysis and test.

Test Sieves for Particle Size Analysis. ASTM 8'''' (203mm) ISO 200mm; ASTM 12'''' (305mm) ASTM 3'''' (75mm) material properties, feed size and volume of the sample, grinding time and desired final particle size, The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions,

WhatsApp)

WhatsApp)