Grinding materials to nanosize? ResearchGate

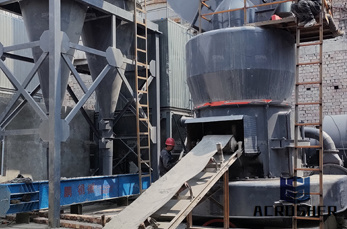

Grinding materials to nanosize? The ball milling is an environmentallyfriendly, costeffective technique. The ball mills can be divided in two groups: direct and indirect milling.

WhatsApp)

WhatsApp)

Grinding materials to nanosize? The ball milling is an environmentallyfriendly, costeffective technique. The ball mills can be divided in two groups: direct and indirect milling.

Ball mill grinding to nano size nano size material by ball milling, high energy ball mills for nano scale grinding, factors like the choice of dispersion medium or grinding ball size live chat zeta rs nano mill grinding dispersing the nano mill zeta rs is the next development of the worldwide known circulation mill system online.

size from 20 to 200 nanometers, meaning that many operators of bead mills are already grinding and dispersing in the nano range. However, there exist real difficulties in the effective design, development and delivery of nanoparticles, most particularly in the area of dispersion. Just as the benefits of nanoparticles are

Since our inception in 2001, we have been engaged in manufacturing, exporting and supplying top grade Media Mill For Nano with the use of qualitychecked components and ultramodern techniques, this mill is widely used for grinding applications in varied industries.

Planetary Ball Mill PM 100 RETSCH highest fineness. Powerful and quick grinding down to nano range. between these forces produces the high and very effective degree of size reduction of the planetary ball mill.

The grinding result is influenced by a number of parameters, especially by the rotational speed of the mill, the grinding time, the ball size, the ratio of the sample quantity to the ball filling as well as the material of the grinding parts. Grinding into the Nano Range.

offers 1,039 small nano grinding mill products. About 2% of these are Mine Mill, 19% are Grinding Equipment. A wide variety of small nano grinding mill options are available to you, such as local service location, applicable industries, and warranty.

From Boulder to NanoParticles John Morris Scientific. Planetary Ball Mills like pulverisette 4, pulverisette 5, pulverisette 6 and pulverisette the material adheres to the bowl wall and the grinding balls and it is minutes (line 5) that has the appropriate particle size for further attempts to produce Nano walls and thus provides the best cost/performance ratio of any

ball mill grinding to nano size. For nanogrinding in a ball mill the grinding jar and balls have to be of a very abrasionresistant material such as zirconium oxide to minimize contamination of the sample material by abrasion Factors like the choice of dispersion medium or grinding ball size have a

Cost Of Ball Grinding Mill For Nano Size Grinding. xperimental setupall milling is a method for fine powder grinding and fabrication of submicron or nanostructured powder materials ll mill is used for the purpose of grinding all kind of mines and materials 10, 11roughout the years, it has proved to be an effective and simple technique to produce nanocrystalline powders and the

Grinding Down to the Nanoscale with Planetary Ball Mills. Apr 03 Function diagram of planetary ball mill The grinding result is influenced by a number of parameters especially by the rotational speed of the mill the grinding time the ball size the ratio of the sample quantity to the ball filling as well as the material of the grinding parts Grinding into the Nano

A wide variety of nano grinding mill options are available to you, such as easy to operate, automatic, and flexible manufacturing. You can also choose from manufacturing plant, energy amp; mining, and building material shops nano grinding mill, as well as from 1 year, 2 years nano grinding mill, and whether nano grinding mill is none, or viet nam.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

In addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced. When the mill capacity is reduced by 75% (5 tph) and grinded with Cylpebs, the fineness (d 90) of the product reaches 1300 nanometers. Key words: Ball Mill, Ball, Calcite, Cylpebs, Nano Grinding. 1. Introduction

WhatsApp)

WhatsApp)