(PDF) Energy and Cost Analysis of Cement Production

The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. Energy consumption data collected for the period 2003 to 2011 were used to estimate

WhatsApp)

WhatsApp)

The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. Energy consumption data collected for the period 2003 to 2011 were used to estimate

Dr Clark has spent most of the last month developing manufacturing cost profiles for cement factories in different geographies of the world. Such profiles help cement producers and traders alike in finding the right location to produce or source cement.

A wide variety of cost of cement plant options are available to you, There are 1,635 suppliers who sells cost of cement plant on, mainly located in Asia. The top countries of suppliers are China, India, from which the percentage of cost of cement plant supply is 99%, 1% respectively.

Cement manufacturing plant cost. Concrete batch plant cost of freight is mainly a variety of vehicle fuel consumption and it includes the cost of concrete mixer cement mixer pump concrete mixer truck and wheel loader Generally concrete batching plant cost of freight can be calculated by actually statistics.

Project ProfileMINICEMENT PLANT. A. TOTAL INITIAL INVESTMENT COST 7913 B. PRODUCTION of a MiniCement Plant with a plants with a capacity of 200 tonnes per day or less are

#0183;#32;Optimizing operating costs to improve profitability in a cement plant The Cement Industry is under increasing pressure to become more profitable. Globally, there is overcapacity of production. To be competitive, Production Units need to optimize operations to the

Full detail on Business Plan for Cement Production, manufacturing plant, cost, plant design, manufacturing project, suppliers, manufacturing process, analysis report, machinery and much more detail to start your industry.

You are facing years of legal hurdles and zoning ordinances to get through, just the paperwork and buying of the property would be up in the tens of millions. The actual construction would be around a billion dollars or so. This would vary greatly depending on your desired output for the the plant. Figure a minimum of 500 million.

#0183;#32;According to the data we know, the total cost of a cement plant is estimated to be US 75 to US 100 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone mines, etc.

Cement manufacturing components of a cement plant

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement manufacturing Process Source: The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1.

The cement manufacturing industry is identified by North American Industry Classification System Cost of materials (1,000s) 354,774 2,479,050 14% Value of shipments is a relatively small plant that produces white cement. The remainder of the natural gas usage is

#0183;#32;Re: cement plant cost A rule of thumb would be that a 2 million tonne per year cement plant would require 300 million US for the equipment, construction and commissioning.

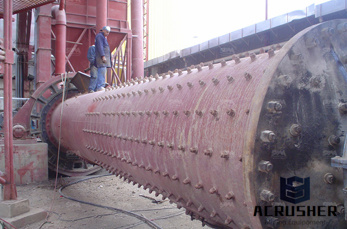

The cement manufacturing plant can be divided into five steps: Crushing amp; prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them.; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.; Clinker production: In the cyclone preheater system, the raw material powder exchange

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Factors affect concrete batch plant cost Materials Influence Costs Of A Concrete Batch Plant. Cement, sand, fine sand, gravel, fly ash, slag, admixture and all other materials costs can be relatively simple calculation according to the ratio and the unit price of raw material. Why raw materials will influence cost of concrete batch plant?

WhatsApp)

WhatsApp)