3 Flow Diagram of Dry Process of Cement Flow Diagram

3 Flow Diagram of Dry Process of Cement Flow Diagram of Wet Process of Cement from PROPERTIES CIV 1236 at Mirpur University of Science and Technology, AJamp;K

WhatsApp)

WhatsApp)

3 Flow Diagram of Dry Process of Cement Flow Diagram of Wet Process of Cement from PROPERTIES CIV 1236 at Mirpur University of Science and Technology, AJamp;K

#0183;#32;The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process the materials are ground and mixed dry. The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure

The wet process of cement manufacturing refers to grinding raw material into slurry after mixing with water and then feeding them into the wet process kiln for drying and calcination and finally forming clinker. The slurrys water content is usually between 32%36%.

#0183;#32;Wet Process for Manufacturing of Cement. Materials. Jun 22, 2016. Tanvi Lad . Tanvi Lad. Tanvi Lad is a Senior Manager (Civil). She gained her BE in Civil Engineering Degree in 2013. She leads Estimation and Tendering Department of SDCPL.

Flow Diagram of Dry Method of Manufacturing of Cement. (i) Preparation of Slurry: In Wet Process, raw materials are supplied to the kiln in the form of an intimate mixture with a

Wet process of cement manufacturing (Flow chart) The length of the rotary kiln may vary anything from 30 meters to 200 meters. The slurry on being sprayed against a hot surface of a flexible chain loses moisture and becomes flakes. These flakes peel off and fall on the floor.

#0183;#32;Types of Cement Processes Wet Process. Dry Process 74% of cement produced. Preheater/Precalciner Process. 16. Evolution of the cement Process Wet process easiest to control chemistry amp; better for moist raw materials. Wet process high fuel requirements fuel needed to evaporate 30+% slurry water.

#0183;#32;Cement manufacturing process components of a cement plant from quarry to kiln to cement mill. Skip to content. Menu. Home; Resources. Civil PowerPoint Presentations | Civil ppts; Cement Manufacturing Process Simplified Flow Chart. March 15, 2017 May 11, 2013 by Johnny.

Jul 9, 2020 cement manufacturing process, cement production process, clinker, flow diagram of cement production, manufacturing process of cement by wet process, preheating tower Cement is the most significant material used in construction and it acts as a binder that can adhere to the materials.

Jul 9, 2020 cement manufacturing process, cement production process, clinker, flow diagram of cement production, manufacturing process of cement by wet process, preheating tower Cement is the most significant material used in construction and it

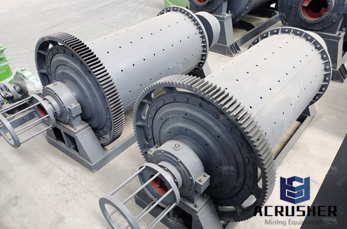

CEMENT MANUFACTURING A WET PROCESS WITH THE FLOW DIAGRAM In the wet process, 1) The raw limestone from quarries is first crushed to small size fragments. Then it is mixed with clay or shale in ball or tube mill and ground to form a

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement ki...

process flow diagram wet process cement . process flow diagram wet process cement manufacture philippin Get Price And Support, #187; mobile rice mill for sale philippines Cement Plant Process Flow Chart, .

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

Figure: Flow Diagram of Wet Process. The clinkers as obtained from the rotary kiln are finely grounded in ball mills and tube mills. During grinding a small quantity, about 2 to 3% of gypsum is added. If gypsum is not added, the cement would set as soon as water is added. The gypsum controls the initial setting time of cement.

Cement Manufacturing A Wet Process with Flow Diagram. The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while

Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 C. This temperature begins a chemical reaction so called decarbonation. In this reaction material

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter.

WhatsApp)

WhatsApp)