(PDF) Analysis of ball mill grinding operation using mill

The research allowed to determine the impact of changes in the parameters of the mill and the feed, tumbling ball mills performing size size and mill speed, operating on a given ore.

WhatsApp)

WhatsApp)

The research allowed to determine the impact of changes in the parameters of the mill and the feed, tumbling ball mills performing size size and mill speed, operating on a given ore.

Wet Grid Ball Mill . Capacity: Feed Size: 25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

Determination of Bond index of Birnin Gwari Iron Ore in Nigeria... mill grinding machine. 80% passing size for the iron ore. Table 3 below shows the sieve analysis of the feed of test ore to Ball mill.

Iron Ore Ball Mill Pdf Zur Guten Quelle 2 Budenheim. Ball mill for iron ore ball mill for grinding iron mill for grinding iron ore with capacity of 130tph and iso certificate ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building

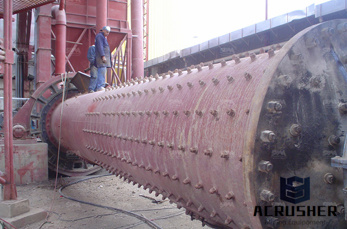

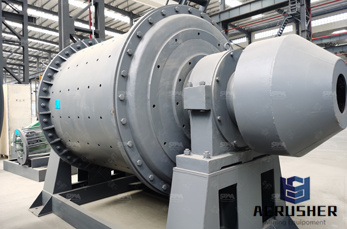

Ball mill external appearance and internal view. Ball mills are filled up to 40% with steel balls (with 3080 mm diameter), which effectively grind the ore. The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in ball/ball

Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials. Rod mill :

To participate in the 911Metallurgist Forums, be sure to JOIN amp; LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone elses

Ball Mills an overview ScienceDirect Topicswhere d bmax is the maximum size of feed (mm); is compression strength (MPa); E is modulus of elasticity (MPa); b feed size ball mill

DOVE Ball Mills are highly efficient size reduction machines, designed for grinding applications, where fine material is required. Applicable for wet and dry grinding applications within the following branches of industries: Mining, Hard Rock (primary deposit) Gold Mining Application, as

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Ball mills, autogenous mills and semiautogenous mills from Thys. senKrupp Polysius tion all around the world, grinding copper ore, gold ore, iron ore and other mineral.. the feed size can range up to 50 mm and in special cases even...

Most iron ore processing plants produce concentrates with Blaine specific surface Investigation on the particle size and shape of iron ore pellet feed using ball mill and HPGR 909 areas of cm 2 g 1 .

The feed ore in primary grinding mills is typically very abrasive owing to its particle size, shape, and mineralogy Wear speeds approaching or exceeding 20 #181;m/hr have been measured for very abrasive Au Cu, and Mo ores, while wear speeds on the order of 1015 #181;m/hr have been encountered in softer primary ores Steel grinding media used in primary grinding must be designed for maximum

impact classifier vs ore and ball mill in rwanda. iron ore product line equipments iron ore ball mill machine line in rwanda Iron ore processing production line Iron ore by the mining crusher preliminary broken in to a reasonable size broken through after lifting machine feeder evenly into the ball the ore crushing grinding by ball mill After the ore fine grinding mill is expected to enter the

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

#0183;#32;An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied. The particle size distribution was meticulously examined by sieve, laser and image analyses. To measure the specific surface area of particles, BrunauerEmmettTeller (BET) and Blaine methods were used.

selection of ball mills selection of iron ore crusher. The selection of ball mill is rely on ore size, necessary output, too as expected ore grade and so on iron ore mining equipment shanghai zenith company, a professional iron mining equipment manufacturer, has been dedicated in

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Feed Size Of Iron Ore To Ball Mill . Ball Millan overviewScienceDirect Topics. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore

WhatsApp)

WhatsApp)