Gypsum Processing for Wallboard Schenck Process

Gypsum Manufacturing US EPA

WhatsApp)

WhatsApp)

Gypsum Manufacturing US EPA

Gypsum is an inert, safe mineral that has been used in a variety of applications the water removed, it can be used to make plaster of paris, commonly used in industry. Chemically, gypsum rock is calcium sulfate with two molecules of water.

Gypsum is normally only screened to remove fines (mainly mudstones), then crushed and finely ground. Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker. C. Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150#176; to 165#176; C, three

Gypsum, unlike cement, is a physical structure rather than a chemical structure. The needlelike gypsum crystals form a network to give the board its physical integrity The crystals are closely interwoven, giving the core most of its wet strength. After drying, the frictional forces of these crystals increase the strength of the core.

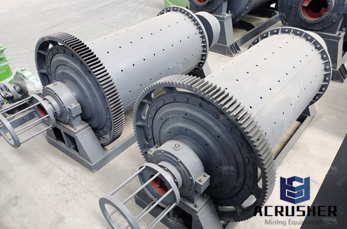

Crushing Sale Gypsum Stone Processing Line . Cone Crushers For Gypsum Processing Equipment XSM Grinding Mill XSM grinding mills vary from coarse grinding, medium grinding to micro fine grinding Grinding MillGrinder Millis widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials processing The materials include line, calcite, barite, coal

It also talks about the list of chemicals used in the tanning process, which hopefully will come handy if some of you would like to start your own leather business. remember to always put extra care to your leather goods for its a very delicate and sensitive material.

Overview: Calcium Sulfate (CaSO 4) more commonly known as gypsum is a naturally occurring white crystalline mineral that has many different uses and in its hydrated form (CaSO 4 2H 2 O) is used in the construction industry for fire resistance in buildings. Outside of the construction industry, gypsum is used in the food and fertilizer industry for calcium and sulfate

Gypsum is the name given to a mineral categorized as calcium sulfate mineral, and its chemical formula is calcium sulfate dihydrate, CaSO 4 2H 2 O. However, a broader definition includes all the calcium sulfates, including calcium sulfate hemihydrate, CaSO 4 2 O, which is known as plaster or plaster of Paris (POP). Figure 6 summarizes the polymorphism of calcium sulfate; g

The use of related additives can significantly improve the performance of gypsum products. Our MelaColl TM cellulose ether products are specially formulated additives that can enhance the performance and processing features of the gypsum products in the following ways:. Enhanced water retention and extended working time

Calcium sulfate (or calcium sulphate) is the inorganic compound with the formula CaSO 4 and related the form of anhydrite (the anhydrous form), it is used as a particular hydrate is better known as plaster of Paris, and another occurs naturally as the mineral has many uses in industry. All forms are white solids that are poorly soluble in water.

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 #183;2H 2 O. It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and massive finegrained white or lightly tinted variety of gypsum, called alabaster, has been used for sculpture by many cultures including

Preparation of Plaster of Paris Plaster of Paris is prepared by heating gypsum (CaSO 42H 2 O) to a temperature of 373 K in a kiln Actually the chemical name of gypsum is calcium sulphate dihydrate which means that the molecule of gypsum is in fact molecule of calcium sulphate which contains two molecules of water of crystallization So when

Gypsum Calcining Metallurgist amp; Mineral Processing . Gypsum is the crystalline chemical compound CaSO4#183;2H2O. A close chemical relation and frequently occurring with Gypsum is Anhydrite which is CaSO4. Gypsun has wide commercial use because relatively simple heat processing reduces it

CHEMICALS USED IN PULP amp;PAPER MANUFACTURING AND COATING. While there are about 3000 or so different types of chemicals which quot;can be usedquot; in papermaking, in practice only about 200 individual chemicals are typically used, each satisfying a specific need.

WhatsApp)

WhatsApp)