Rubber lining of chemical equipment for service in wet and

Chemical and Petroleum Engineering June 1966, Volume 2, Issue 6, pp 409410 | Cite as Rubber lining of chemical equipment for service in wet and dry chlorine gas; IRP1212 and IRP1213 linings

WhatsApp)

WhatsApp)

Chemical and Petroleum Engineering June 1966, Volume 2, Issue 6, pp 409410 | Cite as Rubber lining of chemical equipment for service in wet and dry chlorine gas; IRP1212 and IRP1213 linings

About us. DURATUF is an Indian Rubber amp; Plastic Products supplier offering a huge range of industrial products and related services encompassing Mechanical, Civil,

Our Company is equipped with full fledged in house facilities to carry out Fabrication, Rubber lining and Testing for all chemical Equipments and Pipes and Fittings. Our Company has also been approved by Third Party Inspection Agencies like TATA projects Ltd., SGS

Rubber Lined Tanks amp; Vessels are generally meant to store compressed as well as liquid gases apart from acids and corrosive chemicals. Rubber lined tanks suppliers ensure that these products, including vessels are having rubber linings that prevent them from corrosion by having high resistance against corrosive and abrasive fluids as well as they do possess antivibration features.

CODE OF PRACTICE FOR LINING OF VESSELS AND EQUIPMENT FOR CHEMICAL PROCESSES PARTI RUBBER LINING ( First Revision ) SECTION 1 GENERAL 1 SCOPE This Indian Standard (Part 1) specifies requirements for the lining of equipment for the process industries using cold rubber. It applies to equipment fabricated in metal or concrete.

Rubber Lined Tanks amp; Vessels are generally meant to store compressed as well as liquid gases apart from acids and corrosive chemicals. Rubber lined tanks suppliers ensure that these products, including vessels are having rubber linings that prevent them from corrosion by having high resistance against corrosive and abrasive fluids as well as they do possess antivibration features.

Jasmino Polymertech Private Limited Service Provider of Chemical Process Equipment, Rubber Lining Division amp; Heat Exchanger Tube Sheet from Mumbai, Marashtra, India

Rubber Chemical Process Process Equipment Rubber Lining Chemical Process Equipment These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

The rubber compound is manufactured as per the requirements after looking in to the chemical and other conditions of the process. Rubber sheets are made on calendar machine in different plies. Lining up to 6 mm thickness can be applied in single layer. If the thickness is more, it is applied in 2 or more layers. For Pipes amp; fittings Extruded

Futureready drive and control solutions for rubber processing. Your rubber equipment deals with the here and now, from mixing your recipes to processing and finishing your materials, it is integral to the rubber manufacturing your mind is on a whole range of challenges, from tomorrow''s rubber mixing recipes to efficiency and a quickly changing market.

Although it has been recognized worldwide that rubber lining is one of the most effective means of protecting chemical plant and equipment against corrosion and abrasion, a comprehensive and authentic document was hitherto not available for the guidance of users, equipment fabricators, rubber lining contractors, and applicators that suggested materials and methods of application and testing,

rubber lining for tanks: chemical industry To protect your equipment from corrosion in piping and storage tanks in the chemicals industry, you need a trusted chemicalresistant rubber tank lining. Figuring out which chemical tank lining is best suited for your application depends upon many factors, not the least of which is chemical type, concentration and service temperature.

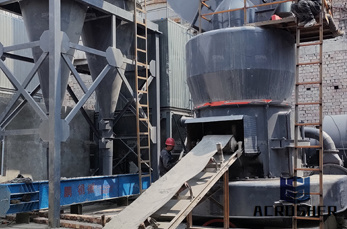

Equipment: Number: Rubber Lining Factory: 1,500 Storage Yard: 6,000 Grid Blast Workshop: 1: Sand Blast Workshop: 1: LargeSized Vulcanizing Autoclave (4,000#248; x 15,000L) 1: MiddleSized Vulcanizing Autoclave (2,500#248; x 5,500L) 1: Other Vulcanizing Autoclave: 3: Gate Type Hoist Crane (5TON x 2) 1: Ceiling Hoist Crane (10TON) 2: Ceiling

We are providing customized solutions of our wide range of Fabrication amp; Rubber Lined (MSRL) Mild steel equipments such as a vessels, Chemical Storage Tanks, Rubber lined spool pipes amp; fittings, Transport vessel (Road tanker), Separators, Agitators, pulley Lagging, Rollers, BFV valves lining, fan/blower blades amp; rotor and drums etc., Rubber Fenders, Rubber sheets, wide range of rubber to

Syntholine offers wide range of Lined Valves, Piping, Fittings and Reactor Accessories for chemical equipments meeting International Standards like ASME, ANSI, ASTM, DIN, BS and more. We have full range of polymer lining like PTFE, FEP, PFA, PVDF, ETFE, PP and HDPE. A great, easy way to prevent metals from corroding.

Rubber lining provides a costeffective method to protect investments and reduce ongoing maintenance costs. In the case of equipment refurbishment involving replacement of worn or damaged linings, high pressure water stripping can be utilised for removal prior to fabrication repairs and modification.

Jemond Rubber Pvt. Ltd. is established in the year 2009 with the objective to provide best rubber lining service. Today we are widely known as the supplier of varied rubber linings

Rubber Lined Equipments are known for their long term protection against abrasion, corrosion and even chemical attack. These products are designed from top quality materials of natural rubber or different varieties of synthetic rubber. These equipments for rubber lining are designed by initially preparing the base metal surface, followed by preparing the rubber sheets, then the application of

Chemtech Rubber Lining (I) Pvt Ltd., has emerged with a vision of acquiring expertise in executing the job of Rubber Lining. Based in Hosur,Tamilnadu. Our Company was established in 2008 and our promoters of the company are having very rich experience in the field of Fabrication and Rubber Lining for more than 25 years.

WhatsApp)

WhatsApp)