Design Of Ball Mill For Quartz

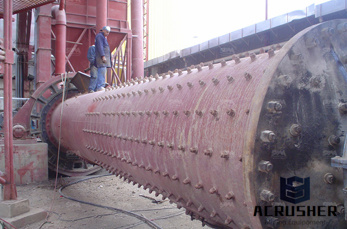

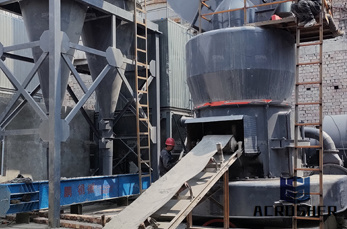

Ball Mill Design, ball mill for quartz crushing Zenith. Ball Mill Design. Zenith Group offer professional ball mill design and export. By adopt the advanced technical of

WhatsApp)

WhatsApp)

Ball Mill Design, ball mill for quartz crushing Zenith. Ball Mill Design. Zenith Group offer professional ball mill design and export. By adopt the advanced technical of

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into fine powder. The cylindrical jar is used as a mill that would rotate the

#0183;#32;The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific

#0183;#32;This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

ball mill design for Ore Beneficiation Plants Desgn Model For Ball Mill. ball mill SBM model d2600xl6000mm Crusher South Africa. Read more design of ball mill for quartz

With a view to developing a sound basis for the design and scaleup of ball mills, a large amount of data available in the literature were analyzed for variation of the two key mill performance

Design Safer Chemicals Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: 8 mm Final fineness: ~ 5 #181;m Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed

The ball impact energy on grain is proportional to the ball diameter to the third power: 3 E K 1 d b. (3) The coefficient of proportionality K 1 directly depends on the mill diameter, ball mill loading, milling rate and the type of grinding (wet/dry). None of the characteristics of

involve grinding). With Lloyd''s ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd''s research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

1,592 ball mill design pdf products are offered for sale by suppliers on A wide variety of ball mill design pdf options are available to you, such as none, egypt, and canada. You can also choose from farms, manufacturing plant, and hotels ball mill design pdf, as well as from nigeria ball mill design pdf There are 37 suppliers who sells ball mill design pdf on, mainly

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of #188; to The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition.

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

ball filling during quartz grinding and the scaleup of laboratory mill results to fullscale. 2. Theoretical background Lets consider a mass of material M in a ball mill that after breakage needs to be divided, by using x i screens, into i + 1 narrow size classes. Normally, for a size class i bounded between two successive screens x i and

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

obtained for some specific grind size that characterizes the grinding operation to design or under evaluation. This study was carried out in a standard bond ball mill 305 mm x 305 mm size in mineral processing laboratory, in the mining engineering department at King Abdulaziz University, KSA as shown in

WhatsApp)

WhatsApp)